For all but the very highest force requirements, electric servo presses provide numerous advantages over their historic, hydraulic counterparts. The actuator is integral to press capability, as well as production quality, and levels of productivity, making its specification central to electric servo press design.

Gerard Bush, engineer at INMOCO, discusses the motion requirements for linear servo press design.

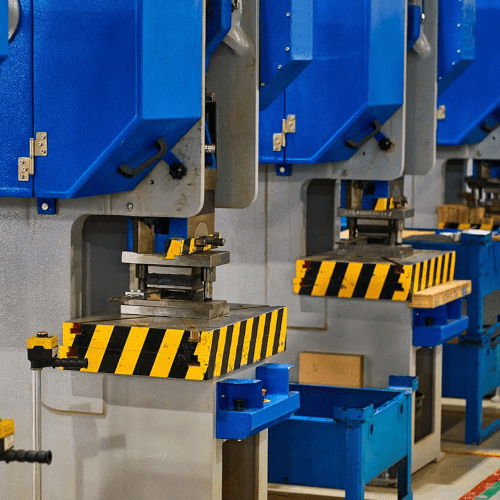

For applications ranging from microelectronics assembly, through to metal bending and forming, presses remain vital industrial tools. Traditionally hydraulically driven, these days, an electric servo press, such as those developed by Tolomatic, can generate force up to 50 tons, or 100 tons in a dual actuator configuration, enabling an electric system to handle all but the highest force requirements.

Often, the primary reason to choose an electric servo press is that it can achieve significantly higher precision, optimising performance by following programmed motion profiles. Combined with continuous monitoring of ram force, speed, and position for real-time adjustment, this adds high accuracy and repeatability. Greater flexibility over motion profiles can also be achieved, and digital actuation enables easier integration into factory automation systems, as well as meeting modern safety protocols.

Electric actuation also makes operation of a press more energy efficient – up to 70% more compared to hydraulics. With fewer mechanical components, electric systems are also more reliable, increasing productivity. With the elimination of fluid leaks, material contamination, and environmental risks, electric servo presses are also significantly quieter.

Motion requirements

A linear servo press is the optimum choice compared to a rotary motion approach as the design removes the inefficiencies of rotary-to-linear linkages. This enables the press to exert higher force with greater precision – also making it more efficient and reliable. This design utilises a direct-drive linear actuator, with a servo motor directly driving a screw mechanism, converting torque into a linear force. The press fixture itself is typically coupled directly to the thrust rod end of the screw assembly.

The role of the actuators is vital, and the fundamental consideration is meeting the force and load requirements. This is based on the type and extent of deformation required, as well as material considerations such as hardness, density, thickness, plus variables such as welded seams. These general properties impact the required press tonnage, as well as the levels of force and stroke.

Actuator selection requires sufficient force to handle the maximum load requirements while ensuring accuracy in control, and a new press design should be sized to meet this. In the case of a hydraulic retrofit, however, like-for-like specification is tempting, but this can lead to oversizing. To ensure accurate specification, designers should determine the true peak and continuous working force of the hydraulic cylinder by recording values during operation. Even a pressure estimation within 15 per cent of the actual force will provide a reasonable range. However, beware underestimating the requirements of the duty cycles, which could work the system too hard and present performance issues or lead to maintenance challenges.

While sufficient acceleration is necessary to achieve the required force, speed and its control are also vital to servo press performance. High-speed operation enables higher cycle times and production rates, while precise speed control is essential to production quality, enabling dynamic management across the stroke.

Specifying an actuator

To achieve the required motion characteristics, screw technology choice is also important. While ball screws are suited to applications that require moderate loads at high speeds, and a more cost-conscious selection, planetary roller screws are the premium choice. Spreading the load over a larger area enables significantly higher force transmission, while greater axial stiffness and reduced elastic deformation enhance precision and repeatability.

Fundamental to driving the actuator is motor selection, which could be integrated into the actuator or chosen separately. An integrated motor can simplify and speed up design, and models like Tolomatic’s IMA series are compact, durable, and ideal for lower force applications. Alternatively, using a separate motor enables gear integration if additional force is required – though selection of the motor requires its own motion specification.

While high-resolution position feedback can be provided by adding an encoder, force control feedback is also necessary. To achieve this, a strain gauge is a cost-effective approach, and its accuracy is sufficient for many general applications. Alternatively, using motor torque feedback increases accuracy, especially if a load cell is added to calibrate actuator force output. Load cells can also be integrated into the press fixture itself, placing the sensor much closer to the point of force application, resulting in higher accuracy.

Engineering support

To accurately specify the linear servo press, brands like Tolomatic offer sizing software that can manage complex calculations including desired motion profiles. If designers have bespoke requirements, or prefer to talk in person, they can discuss their needs with INMOCO’s engineers who can advise on specification and coordinate with established actuator manufacturers.

Specifying an actuator for a press doesn’t end with motion requirements. Achieving safety standards is vital, including providing necessary safety features. In the heavy-duty environment where presses operate, they must also be sufficiently durable to deal with temperature, humidity, dust, washdowns, and vibration. They must also be able to integrate with the host automation and control system and enable straightforward set up. To maximise productivity, the actuators must also offer long-term reliability, combined with straightforward maintenance.

INMOCO’s engineers, supported by Tolomatic’s engineering team, can provide linear servo press designers with a holistic service that accommodates all the requirements of specification.

About Tolomatic

Since 1954, Tolomatic has been manufacturing innovative automation components. From gearboxes and brakes to pneumatic actuators and complete electrical linear motion systems, Tolomatic’s motion solutions are designed to move businesses forward. For more information on Tolomatic products: Please visit tolomatic.com