Genomics advances are changing the world. By mapping the DNA of living organisms human and animal health can be improved, diseases eradicated and crop plants strengthened to increase their yield. It is a relatively young science, largely based on Francis Crick and James Watson’s discovery of the DNA double helix in 1953 and still has a great deal of potential for further advancement. Human biomedical research, plant and animal biology, microbiology, and infectious disease research are all benefiting hugely from genomic research and development.

However the genome scientists face many challenges in their work, not least of which is developing equipment that allows them to do their work. As with most fields of scientific research, experiments often require a lot of repetition so that statistically significant bodies of data are built up. Thus automated systems are not simply attractive labour saving devices but are absolutely essential if accurate replication is to be achieved. Further, as with many biological fields, work is done at a cellular scale, so precision microscopic motion is a necessity.

There are also practical considerations when it comes to designing DNA laboratory equipment. For instance, it has to be compact because space is always at a premium in laboratories. Also of increasing significance, the constant pressure on science budgets is leading to a need to reduce the energy consumption of the equipment, particularly when it is required to run continuously for long periods of time.

An automated sequencing system for genomic research which observes the minute amounts of light generated by the natural process of DNA replication has been enabled by Celera Motion, an American company represented in the UK by INMOCO. Celera makes precision components and integrated mechatronic systems that solve application-specific challenges for technology driven original equipment manufacturers (OEMs) around the world.

Like many systems integrated with Celera’s technology, the sequencing equipment requires extremely precise sample positioning under the light detection optics. One of the critical requirements for the system was fine positioning of a six axis (hexapod) stage and for this Celera used one of its Mercury II programmable encoders paired with a piezo electric motor stack. The encoder provides the user with exceptionally high resolution and low pass noise filtering. It also has integrated end of travel limit signals, and low power dissipation in the head as well as customised sensor cables for ease of installation. During measurement, the hexapod motors are turned off to reduce vibration and to help stabilise the temperature because position stability is of such crucial importance.

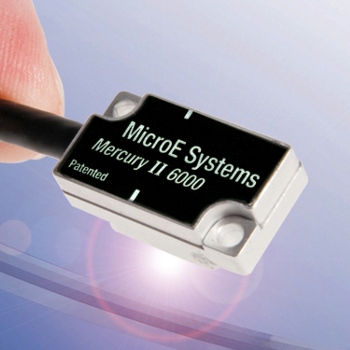

The Mercury II 6000 optical encoder is non-contact and operates on a 20µm pitch diffraction scale with integrated index and left/right limit marks. With up to 16,384-times interpolation it boasts a user programmable resolution between 5 µm and 1.22nm. External digital interpolation keeps the power dissipation in the sensor head low and a digital low pass input filter provides excellent position stability by rejecting high frequency noise sources.

The encoder is tiny; weighing only 6g it measures 32mm x 13.5mmx 8.7mm. With grating dimensions of 15.0mm x 6.0mm x 2.5mm (including index and limits) it has a system resolution of 1.22nm and runs at speeds up to 48.8mm/sec. Its interface is digital A-quad-B.

Celera Motion is renowned for its core technologies, which includes MicroE encoders and Applimotion motors and actuators that are designed for the most demanding motion control applications and for its ability to analyse, understand and meet project requirements.