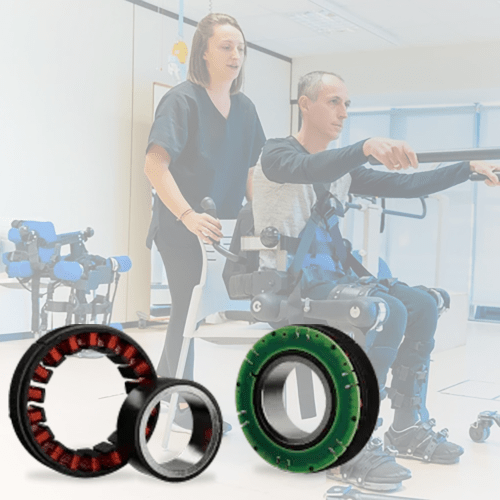

Requiring compact, low weight, and torque-dense motion systems, exoskeleton designers continue to see the advantages of frameless brushless DC (BLDC) motors with harmonic gearing. Particularly for complex, multi-jointed exoskeleton applications, engaging the right support in motion development from the outset can save significant project development time.

Gerard Bush, engineer at motion specialist INMOCO, explains.

Once the dream of a bionic future, today, exoskeleton technology is moving into the mainstream. With a high strength, lightweight support for upper or lower limbs, the crucial advantage provided by the exoskeleton is motorised propulsion that enhances human capabilities. The technology has already shown potential in medical and care sectors, where exoskeletons have been used for rehabilitation and to enhance independent living for people with disability. Exoskeletons are also starting to be used in workplace settings to increase safety, reduce strain, and improve productivity.To move exoskeletons further into the mainstream, the technology’s emphasis on development is to achieve designs that are highly functional well as easy to wear and use. This means a compact design that is suitably powerful, but lightweight too, with a sufficient period between battery charges.Central to meeting these needs is the power plant, based on electric motor technology. To specify this system, fundamental considerations depend on load characteristics combined with requirements in motion dynamics, prioritising user safety, plus reliability and efficiency. Alongside mapping out these criteria, the most effective motor technology can be selected.

Frameless motors

Frameless BLDC motors are a strong choice for exoskeletons because of their compact size and low weight. The design includes rotor and stator components that are built into the host machine, but rely on the machine’s housing for protection. Like a typical servo system, a frameless BLDC motor still requires a feedback device, which sends its speed and position to a drive that controls the desired output.

Free of the wider components that housed motors comprise, frameless motors can support an exceptionally compact, lightweight design. As frameless motors feature a large inner diameter centre bore that can accommodate encoders, cables, and shafts, this also enhances their integration into the robotic joints of the exoskeleton.

Relying on the structure of the exoskeleton for protection, these motors also achieve the same ingress protection and impact resistance as their host. If high operating temperatures are present, the structure of the exoskeleton can also offer heatsinking, enhancing user comfort and safety.

Gear requirements

Frameless motors are often driven directly, where the rotor is mounted to the host, powering the load without a gearbox, to reduce backlash and increase efficiency. However, the demands of an exoskeleton application typically require gear reduction. Particularly for lower-limb joints, relatively high torque is required for tasks such as standing up or walking uphill. Adding a gearbox means that a low size and weight of drive system can be maintained while achieving the required torque. Moreover, gear reduction achieves the low speed required to match slow movement, necessary for safe exoskeleton assistance.

The most fitting type of transmission is harmonic drive gearing, also known as strain-wave or sinusoidal gearing. This gear uses a rotating elliptical wave generator to elastically deform a flexible, toothed cup, which is engaged by a rigid outer ring. Tooth differences between these three components achieve a variation in rotation that delivers a high gear reduction ratio. The advantage for exoskeleton applications is high torque generation, combined with smooth transmission with zero backlash.

Frameless BLDC motors such as the Kollmorgen TBM2G integrate directly with harmonic drive gearing, with diameters extending from 50 mm to 115 mm to cover a broad range of exoskeleton requirements. This torque-dense design also delivers high torque at high speed, which can decrease the size and weight of the required gearbox.

Motion development expertise

Returning to the specification criteria for the original motion system, the complex relationship between the load and dynamics of each joint can require revision after the various components have been selected in concept. For example, if the weight of the gearbox and motor combination for a knee joint is greater than expected, this could subsequently increase load demands on the hip joint, as well as raising operating temperatures.

To reduce design time, specifying torque-dense motors from the outset, with headroom for adjustment, enables faster updates if subsequently required. Alternatively, if designers reach a torque ceiling and require a high gear ratio, speed may be sacrificed. Here, the high-torque-at-high-speed design of the TBM2G motor is also advantageous for design flexibility.

At INMOCO, we’ve supported exoskeleton developers in the UK with the delivery of motion system projects across varied applications. Providing specification advice in design, we also partner with brands like Kollmorgen to supply motors, as well as drives and controls.

While the complex field of exoskeletons continues to develop, specialised knowledge in motion system design is helping to propel these applications into the mainstream.