Rod-style electric actuators with integrated servo motors are reducing machine footprint and extending service life. INMOCO is supplying Tolomatic’s high force Integrated Motor rod-style Actuators to the UK. Tolomatic’s IMA actuators have been developed for OEMs requiring high force in a compact, highly durable and long lifetime package.

Tolomatic IMA provides up to 30.6 kN push and pull force in a highly compact, integrated servo motor and actuator design. This design reduces the overall footprint of the machine by removing the need for an external motor. The integrated approach also simplifies machine design and installation which can be further extended with a single cable option if a Hiperface DSL encoder is used.

Tolomatic’s IMA utilizing roller screw technology is ideally suited for pressing applications, where high force and long life are required. Efficiency, accurate positioning and quick response also makes the IMA ideal for valve management, as well as process control applications such as fluid dispensing. In these applications repeatable force with smooth velocity are necessary. IMA has also been designed for resistance spot welding applications It’s light weight and compact construction are ideal for pedestal and robotic applications in addition to very repeatable and consistent force. IMA is also a cost effective option for welding applications with a competitive price point.

IMA has been specifically designed and tested to maximize service life. A grease port means lubrication can take place without the need for removal from the machine. This increases the potential for regular, simple lubrication extending the screw service life. The roller screw supports this by applying force over a large contact area, reducing concentrated wear thus increasing force and minimizing the space required to do so when compared to conventional ball screws. Should applications not require the extended force or durability provided by the roller screw, ball screws are available for increased cost efficiency.

The IMA’s robust construction is further enhanced with an IP65 rating. This provides ingress protection from dust and water spray, supported by a replaceable rod wiper preventing contaminants from entering the actuator. An IP67 option is also available, protecting from water immersion up to 1m depth for 30 minutes. Internally, the steel thrust tube supports extremely high force capabilities and its salt bath nitride treatment provides high surface hardness, corrosion resistance, and other hazards like weld slag, water or other potential contaminants. Meanwhile, bumpers protect the screw and nut assembly from damage at the end of stroke in the event of an uncontrolled impact.

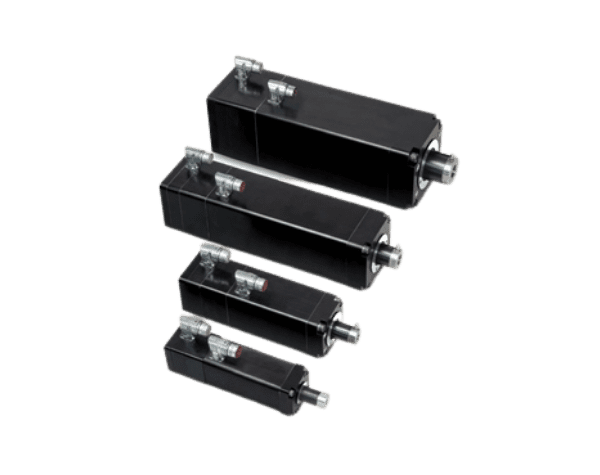

Tolomatic IMA generates actuation speed up to 1,334 mm/sec with a stroke length up to 457 mm, in face sizes ranging from 63.5 mm to 142 mm. Integration with leading robot manufacturers is made possible through wide array of feedback types, resolutions, and protocols. The recent addition of the Hiperface DSL option also enables a single cable solution integrating power and feedback, for a more compact footprint and simpler installation.

IMA is quieter and cleaner than hydraulic systems, as well as removing the possible emission of hydraulic fluid. Also included in the IMA range is a white paint option. This adds options that are very desirable for food manufacturing and processing applications. With a painted exterior, an IP67 option, stainless rod and food grade grease, it is a cost effective solution in a very compact package. The newest addition to the IMA family is the IMA-S. An all 316 stainless steel solution with IP69k sealing is the premier solution for the most aggressive wash down and caustic environments.