High-Resolution Multi-Turn Feedback

Kollmorgen has enhanced its AKM and AKM2G servo motor families with a new high-resolution encoder option that provides absolute multi-turn feedback — at no additional cost compared to the existing absolute single-turn variant. The Kollmorgen SFD-M encoder option achieves four times greater positioning accuracy than previous designs. The encoder tracks and maintains the position register even after power off, thanks to an innovative battery-free design.

Precision Sensing and Resolution

Designed to integrate with Kollmorgen’s AKD and AKD2G drives, the new encoder option provides absolute multi-turn position feedback. The absolute encoder achieves actual angular position per revolution in 24-bit resolution. This capability results in high-precision sensing throughout each 360º rotation, with 16,777,216 counts per revolution at 0.0772 arc-sec per count. Accuracy is +/- 1 arc-min, typical at 25ºC.

Rapid Start-Up and Productivity Gains

Registering the number of shaft rotations in either direction, the multi-turn resolution capability is provided at 16 bits, and can track up to 65,536 motor revolutions. Registering absolute multi-turn position, even when the system is powered off, allows machine end users to achieve a rapid system start-up, which is especially useful for machines that involve moves over longer distances. This approach eliminates the need for time-consuming homing sequences when the machine is powered on, optimising productivity and reducing power consumption.

Application Versatility and Cost Efficiency

As a result of this performance, the new SFD-M encoder is well-suited for applications such as machine tool positioning, packaging machines, material handling, satellite tracking, and other applications that require precision position sensing over longer distances.

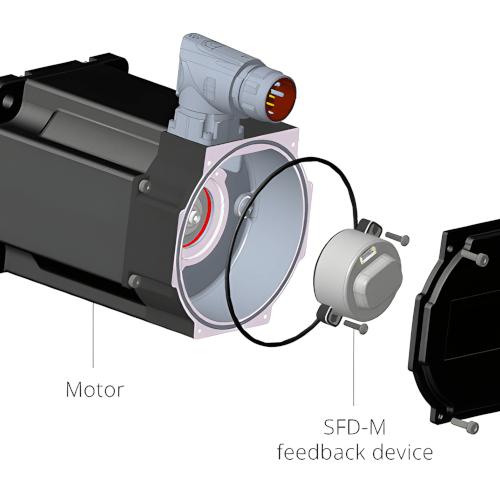

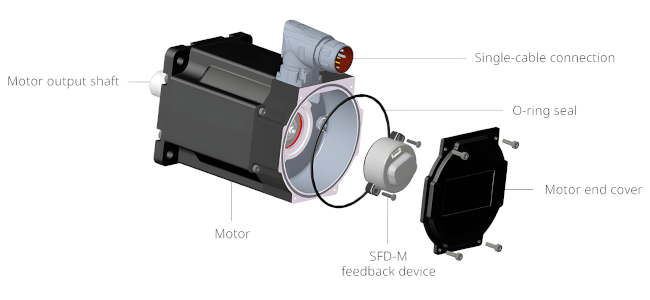

The absolute multi-turn capability is provided at the same price as Kollmorgen’s SFD-3 single-turn absolute encoder. The new device also achieves a significant cost saving compared to integrating a third-party sensor. The new Kollmorgen SFD-M encoder is integrated directly into Kollmorgen’s AKM and AKM2G housed servo motors, saving space and maintaining a low footprint. The design also achieves low electrical noise, up to 50 times lower than previous designs.

Battery-Free Design and Reliability

The encoder’s battery-free design also optimises reliability and minimises maintenance. This is achieved with energy-harvesting technology, removing the challenge of battery failure and replacement, common to other multi-turn encoder designs that use batteries to retain position information after powering down. The battery-free design also reduces size and creates a more sustainable design alternative. The SFD-M encoder’s approach to power supply when mains power is off is also preferable to integrating mechanical gears, which are backlash-prone and add size – and audible noise.

Kollmorgen’s AKM and AKM2G servo motors with the new SFD-M encoder, along with its AKD and AKD2G servo drives, are distributed in the UK by motion control specialist INMOCO.

About Kollmorgen

Kollmorgen has more than 100 years of motion experience, proven in the industry’s highest-performing, most reliable motors, drives, linear actuators, gearheads, AGV control solutions and automation platforms. Kollmorgen delivers breakthrough solutions that are unmatched in performance, reliability, and ease of use, giving machine builders an irrefutable marketplace advantage.