Web tension control is fundamental to applications such as printing, packaging, and textile processing. To achieve a high-quality process and maintain rapid throughput, precise control over the tension and speed of the material is vital. In this article, Gerard Bush, an engineer at motion specialist INMOCO, explains the common architecture of a web tension control application and highlights the crucial aspects required in its motion coordination.

To process sheets of material such as textiles or paper, this involves a web tension control application. When laid out in the machine, the material resembles a web, threaded between unwinding and rewinding spools via a path including the processing station. Whatever the objective of the processing element, whether that’s printing or cutting, or laminating through to inspecting, maintaining the optimum tension of the material is critical, both to ensure the quality of processing, as well as to protect the integrity and form of the material.

A closed-loop system, typically involving DC or brushless motors, is essential to maintain precise control of the material’s tension. As the unwind motor feeds the material from the unwinding spool, its torque must decrease in line with the spool’s continually reducing diameter. Conversely, at the rewind motor, the terminus of the operation, the torque must increase to match the growing diameter of the rewind spool as the material is wound on.

While these two axes can maintain the general tension of the material, they cannot alone control the material’s speed with a sufficient level of precision. Any mismatch between these two axes could cause the material to stretch or jerk, presenting processing challenges at the critical stage.

Constant speed control

To achieve the constant speed required to process the material with precision, independent speed control must be applied through the web’s internal zone. Positioned after the unwinding spool motor, a lead drive sets the line speed as the reference for the synchronisation of the process stages, such as cutters or printers, including the feed speed to the downstream stages.

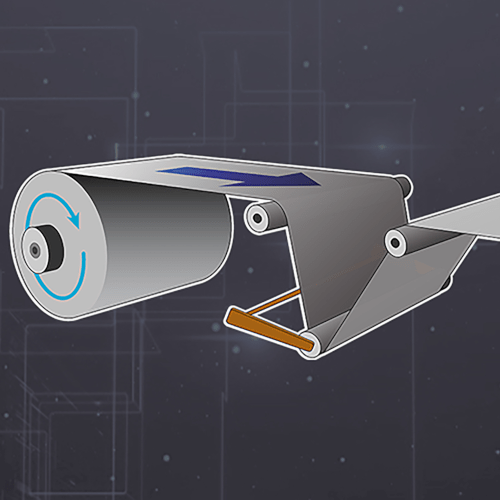

After the processing stage, the follower drive axis controls material tension within the process zone by modulating torque based on tension sensor feedback, while the master drive maintains the line speed. Without this follower axis, tension fluctuations could arise, leading to disruption, misregistration, or even breakages in the material. However, even very small discrepancies between the lead drive’s velocity and the follower’s torque response can create tension fluctuations that impact the quality of the processing stage. As a result, a compliance device, such as a dancer, which is a spring-loaded arm, is required to smooth out this difference.

Integral to the control of the web tension machine, an additional component of the compliance device is a position sensor. The position sensor provides accurate web tension feedback by measuring the deflection of the dancer arm and adjusting for the arm geometry. Instead of a dancer, a sensor device like a strain gauge could also perform an equivalent feedback signal.

Managing speed and torque

While the lead drive is commanded with a velocity provided by the motion controller, feedback from the tension sensor is used to continually modulate the torque commanded by the controller to the follower drive. As a result, key control capabilities include precise command of the lead drive’s velocity loop and the follower’s current (torque) loop, which helps smooth tension during material processing. Techniques that minimise tension oscillation are also important, such as electronic damping in the servo filter, and frequency-based compensation using digital filters like biquads.

A challenge in web tension control arises when the web must accelerate or decelerate instead of moving at a constant speed. This could happen during machine startup, as well as part of intermittent or indexing processes. During these speed changes, the inertia of the web material and the rollers can also change the tension. To resolve this, a feed-forward compensation signal, derived from the acceleration profile of the motion controller, can be applied, helping to anticipate and counteract tension changes before they occur.

For processes that require the highest levels of precision, application-specific software code might also be required. Bespoke programming could compensate for non-standard geometries of the web path, or specific properties of the material, such as temperature, tension, or deflection tolerance. For example, the increased complexity of layering multiple composite sheet webs can benefit from user-customisable control software.

Specifying the motion system

While many web tensioning application designers will have a clear idea of their motion control requirements, guidance in the specification of controllers, drives, motors, and gears can save time in development and help achieve specific performance criteria. Spanning motion requirements through to a machine’s wider control elements, specification advice can also extend to design needs relating to sensor integration and communications.

At INMOCO, our engineers are motion control specialists, and discuss design requirements with OEMs, machine builders, and system integrators on a daily basis. Specifying motion control products to meet specific needs, INMOCO partners with motion control vendors such as Performance Motion Devices (PMD), whose drives are used in a wide variety of web tensioning applications on account of their ruggedness, high performance, and competitive price point. This includes PCB-mountable drive modules supporting multiple sensor input and full customisability, as well as IC-based solutions for BLDC and DC motor control.

This coordinated approach enables operators of processes using web tension to optimise their design and fine-tune the control infrastructure to ensure a consistently high-quality end product. Involving motion engineering expertise is the quickest and most reliable way to achieve this.