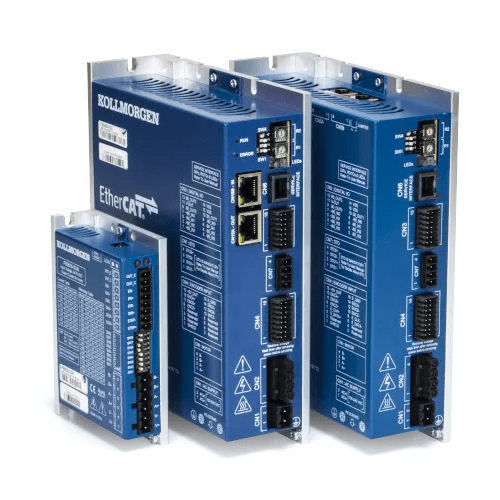

P8000 Stepper Drive

The P8000 Stepper Drive Series is Kollmorgen’s newest flagship stepper drive platform. These drives offer extended output current ranges and functionality enabling our customers to use a wider portfolio of Kollmorgen stepper motors. They are ideal for Indexers, packaging machines, CNC Machines, labellers, pumps and many other applications requiring low-speed, point-to-point motion control for fixed loads. Now available available for DC and AC operation, these drives are designed to power 2-phase hybrid stepper motors.

Features

P80360 Drives:

- 100-240VAC, single-phase power supply input required.

- Dual STO Channels (SIL3/PLe).

- Mandatory 24VDC power supplies required to operate the drive.

- (-ECE Version) EtherCAT subordinate drive using CANOpen over EtherCAT (CoE) conforming to DS402 standard

- Optional Kollmorgen Studio Software (free download in Software tab) for motor setup, parameterization and debugging. EtherCAT Master may be used as well.

- (-R4E Version) Programmable drive with Modbus RS485 RTU onboard

- Uses Kollmorgen Space Software (free download) for motor setup, parameterisation and programming

- 4 Digital Inputs – user programmed

- 5-24V, PNP/NPN/Line-Driver

- 3 Digital Outputs – user programmed

- 24V PNP

- Microstepping resolution up to 51,200 steps/revolution

- Motor Phase Current up to 3.0 Arms/phase

- Closed Loop Position Control capable

- 5V Incremental AB(Z) Encoder only

- Open Loop Stall Detect capable without encoder

- Fault Protection:

- Thermal Protection (Over-Temperature)

- Over-Current

- Over/Under Bus Voltage

- Short Circuit (Phase-to-Phase or Phase-to-Ground)

- UL, CE, RoHS, REACH certified

P80630-SDN:

- Single 24-75VDC power supply input required

- Bipolar chopper drive for superior current regulation and low ripple current

- Conventional Step and Direction interface. User provided pulse train to rotate the motor

- Dedicated inputs for Step, Direction (CW/CCW) and Enable

- Dip-switch selectable settings. No programming required!

- Idle Current Reduction to reduce motor heating during dwell or when holding a load

- Microstepping resolution up to 25,600 steps/revolution

- Motor Phase Current up to 5.5 Arms/phase to pair with widest range of Kollmorgen motors

- Fault Protection:

- Thermal Protection (Over-Temperature)

- Over-Current

- Over/Under Bus Voltage

- Short Circuit (Phase-to-Phase or Phase-to-Ground)

- CE, RoHS, REACH certified

Specifications

| Specifications | Units | P80630-SDN | P80360-R4E | P80360-ECE |

|---|---|---|---|---|

| Input Voltage Range | Volts | 24 – 75 VDC | 100-240 VAC, Single-Phase | 100-240 VAC, Single-Phase |

| Continuous Current | Arms (Apeak) | 1.7 – 5.5 (2.4 – 7.8) | Up to 3.0 (4.2) | Up to 3.0 (4.2) |

| Digital Inputs | – | 3 (Step, Direction, Enable) | 4 (User Programmed) | 4 (User Programmed) |

| Digital Outputs | – | 1 (Fault) | 3 (User Programmed) | 3 (User Programmed) |

| Control Mode | – | Step and Direction (CW/CCW) | Programmable via Kollmorgen Space Software | EtherCAT subordinate |

| Fieldbus Offering | – | None (Open Loop) | Modbus RS485 RTU onboard | EtherCAT DS402 |

| Step Resolution | – | Full-Step to 1/128 (200 to 25600 steps/rev) | Full-Step to 1/256 (51200 steps/rev) | Full-Step to 1/256 (51200 steps/rev) |

| Feedback Support | – | None (Open Loop) | Yes (Closed Loop Position Control), using 5V ABZ Incremental Encoder | Yes (Closed Loop Position Control), using 5V ABZ Incremental Encoder |

| Package Size | mm, WxDxH | 26 x 75.5 x 108 (without connectors) | 50 x 139 x 181 (without connectors) | 50 x 139 x 181 (without connectors) |

| Weight | grams | 200 | 800 | 800 |

| Operating Temperature | Degrees C | 5-40 | 5-50 | 5-50 |

| Max. Chassis Temperature | Degrees C | 70 | 70 | 70 |

| Idle Current Reduction | – | Settable, 50% or 90% | Settable, 0 to 100% | Settable, 0 to 100% |

| Connectors | – | Screw Terminal | Screw Terminal | Screw Terminal |

P80630-SDN Stepper Drive Installation Manual

P80360-R4E Stepper Drive Installation Manual

P8000 Stepper Drive Safety Notes