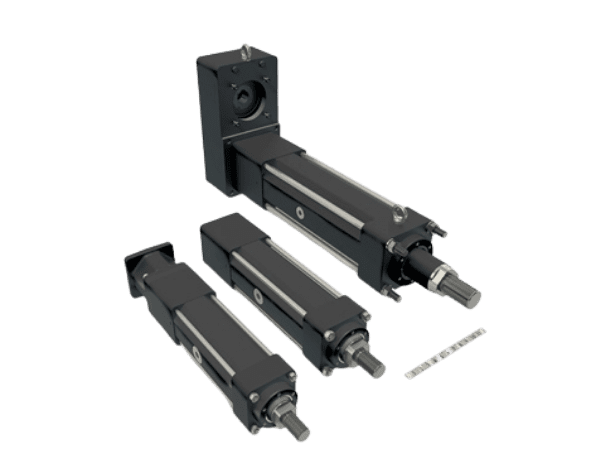

New rod-style electric actuators achieving forces up to 222.4 kN have been released. INMOCO is now supplying Tolomatic’s RSX Extreme Force actuators to the UK market, which also provides high accuracy and a long lifetime. Aimed at OEMs, the RSX electric actuators are an ideal replacement for hydraulic cylinders.

Extreme Force Ratings and New RSX128 Model

The Tolomatic RSX Extreme Force actuators provide force ratings from 80.1 kN to 222.4 kN with 100% duty cycle operation in both the push and pull directions. The range includes the newly released RSX128 actuator, which provides an increase of 60% from the 178 kN total provided by the RSX096P press model.

Application Scope and Hydraulic System Replacement

The actuators have been designed for a wide range of extreme force applications, including pressing, riveting, injection moulding and sawmill equipment. Also targeted at upgrading from hydraulic cylinders, the RSX electric actuators provide enhanced control of speed and position, achieving a roller nut screw accuracy of ± 0.01mm/300mm. Control is also more consistent, removing the fluctuations caused by temperature and pressure changes associated with a hydraulic system.

Speed, Stroke and Anti-Rotation Features

The new RSX128 extreme force linear actuator operates up to a maximum speed of 500mm/second at a maximum stroke length of 665mm and comes standard with an anti-rotation thrust rod, should the application not provide external restraint.

Durability Through Roller Screw Mechanism

The RSX is designed for long life and achieves operational durability as a result of the planetary roller screw mechanism. As opposed to a ball screw, the roller screw mechanism applies force over a larger contact area, reducing concentrated wear and resulting in a higher load capability and longer life. The RSX096P Press model, designed for the highest force actuation, further extends operational durability with oversized tie rods, a bearing system optimised for high force extension, as well as a reinforced strength steel front flange.

Material Protection and Environmental Resistance

For optimised durability, Type III hard coat anodised aluminium housing increases surface hardness to withstand demanding environments, while steel components are black or clear zinc plated for corrosion resistance. The actuator also includes the option of stainless steel upgrades for the motor mount, tie rods, front flange and thrust rod to further increase durability for applications in corrosive environments. With ingress protection from dust and water spray up to IP65 as standard, IP67 is optionally available, providing resistance to water ingress up to 1m deep for up to 30 minutes when static. The RSX actuator is also designed to withstand cold conditions.

Cleaner Operation and Food-Grade Options

Compared to hydraulic systems, Tolomatic’s RSX Extreme Force electric actuators are also quieter in operation as well as cleaner, without the unwanted possible emission of hydraulic fluid. The Tolomatic actuators are also available with a food-grade white epoxy resin coating and stainless steel thrust rod, designed for use in food and beverage processing applications.

Motor Compatibility and Integration Support

The Tolomatic RSX is compatible with a wide range of servo motors and gearboxes up to 215mm frame size under Tolomatic’s Your Motor Here® program. Meanwhile, INMOCO can provide the RSX with Kollmorgen servo motors as a package.

Further Expansion of the RSX Range

On 24 September 2024, Tolomatic announced an expansion of the RSX actuator line with new models offering up to 294 kN thrust and updated naming conventions. These enhancements further extend the RSX’s capabilities across demanding industrial applications.