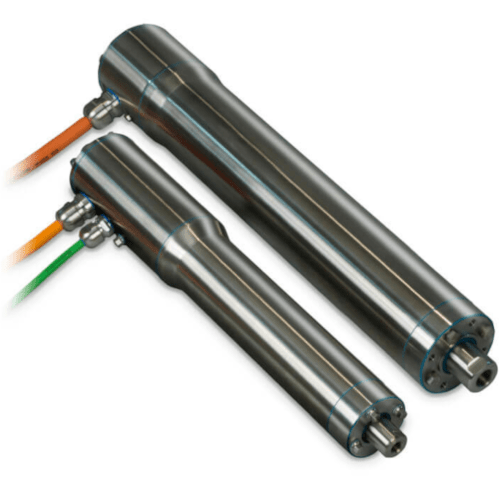

Planetary Roller Screws – High Force, Long Life, Compact Design

A Planetary Roller Screw is a high-performance linear motion technology designed for applications requiring extreme load capacity, precision, and durability. Unlike ball screws, planetary roller screws use threaded rollers to deliver superior thrust and longer service life.

Tolomatic planetary roller screws are engineered for demanding industrial applications and manufactured in the USA using advanced equipment and strict quality controls. With deep case hardness and high Dynamic Load Ratings (DLR), these components are ideal for high-force linear motion systems.

What Sets Planetary Roller Screws Apart?

Tolomatic’s planetary roller screws are engineered for high-force linear motion in compact spaces. Unlike ball screws, which rely on ball bearings, planetary roller screws use precision-ground rollers that engage with a threaded shaft. This design increases the number of contact points, reduces stress per point, and enables significantly higher load capacities.

Compared to ball screws of similar size and lead, planetary roller screws offer:

- Higher Dynamic Load Ratings (DLR) for demanding applications

- Longer service life due to reduced wear and superior contact geometry

- Compact design that supports smaller machine footprints

- Superior shock load handling, ideal for high-impact environments

- Faster acceleration rates, enhancing system responsiveness

These advantages make planetary roller screws the preferred choice for OEMs seeking durability, precision, and space efficiency.

🔍 Roller Screw vs Ball Screw: A Quick Comparison

| Feature | Planetary Roller Screw | Ball Screw |

|---|---|---|

| Dynamic Load Rating | Very High | Medium |

| Lifetime | Many times greater | Moderate |

| Shock Load Capacity | Very High | Moderate |

| Space Efficiency | Minimal space required | Moderate space required |

| Acceleration | High | Moderate |

Planetary Roller Screw Features and Benefits

- Extensively tested in Tolomatic’s R&D lab for durability and performance

- Proven reliability in thousands of global installations

- Configurable stroke lengths to suit custom applications

- Compact, lightweight design enables smaller machine footprints

- Industry-leading lead times for fast delivery

Available Sizes and Leads

| Roller Screw Size (mm) | Available Lead Options (mm) |

|---|---|

| 15 | 4, 5, 10 |

| 20 | 4, 5, 10 |

| 30 | 5, 10 |

| 36 | 5, 10 |

| 39 | 10 |

| 48 | 12 |

| 63 | 10 |