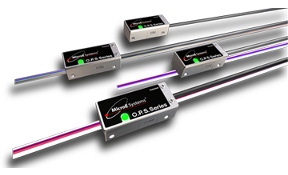

P7000 Series Stepper Drive

Important Notice

The P7000 Series Stepper Drive products are no longer available for purchase as they have been discontinued. For new and retrofit applications, please consider a P8000 Stepper Drive solution.

Overview

The P7000 series stepper drive offers unsurpassed system smoothness, functionality, performance and innovation. Available for AC(P70360) or DC(P70530) operation, these microstepping drives are designed to power 2-phase NEMA stepper motors. They offer unique features that are ideal for single or multi-axis applications requiring high-speed performance or low-speed smoothness.

P70360 AC Stepper Drives

- P70360-SD:

- Conventional step and direction interface

- Dedicated inputs for jog+/-, enable and step/direction control

- User-provided pulse train to rotate the motor

- P70530-PN adds to the base drive:

- Indexing capability, allowing up to 63 independent, programmable moves

- Modbus RTU compatibly

- P70360-R4 adds to the base drive:

- Indexing capability, allowing up to 63 independent, programmable moves

- Modus RTU compatibly

- Adds an RS-485 interface

- Integral power supply

- Input voltage: 120 to 240 VAC (1 phase, 50/60 Hz) for a broad range of power sources

- Continuous current: 2.5 Amps; microstep peak current: 3.5 Amps

- Max shaft power: 525 W

- Speed range: 0 to 50 rev/sec

- Motor inductance: 50 to 200 mH (320 VDC BUS), 7 to 30 mH (160 VDC BUS)

- 9 programmable inputs

- Easy-to-use graphical interface

- Open loop stall detection

P70530 DC Stepper Drives

- P70530-SD:

- Conventional step and direction interface

- Dedicated inputs for jog+/-, enable and step/direction control

- User-provided pulse train to rotate the motor

- P70530-PN adds to the base drive:

- Indexing capability, allowing up to 63 independent, programmable moves

- Modus RTU compatibly

- Input voltage: 20 to 75 VDC

- Continuous current: 5 Amps; microstep peak current: 7.1 Amps

- Max shaft power: 300 W

- Speed range: 0 to 50 rev/sec

- Motor inductance: 2 to 15 mH

- 9 programmable inputs

- Easy-to-use graphical interface

- Open loop stall detection

Benefits

- Ideal solution for single or multi-axis applications that require high-speed performance or low-speed smoothness

- 9 programmable inputs, available indexing model and easy-to-use graphical interface simplify configuration for complex machine requirements

- Integral stall detection eliminates the need for expensive external sensors or feedback, reducing system cost by up to 30%

- Multistepping™ feature inserts fine micro-steps to smooth coarse low-speed motion without having to redesign machine control architecture

- Mid-band anti-resonance control reduces the negative effects of mechanical resonance, allowing you to get more out of a smaller motor and virtually eliminating nuisance stalls and machine downtime

- Dynamic smoothing quasi-S-curve algorithm reduces jerk, especially upon acceleration, increasing mechanical life and reducing energy consumption