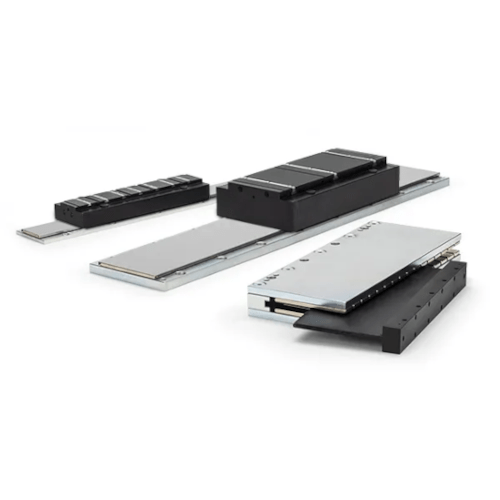

IC Iron Core Linear Motors

IC series iron core linear motors have coils wound around silicon steel laminations to maximise the generated force with a single sided magnet way. The special electromagnetic design of these motors delivers a high motor constant (Km) for low thermal losses, the highest rated force per size, and low cogging forces. The high thrust forces possible with these motors make them ideal for accelerating and moving high masses, and maintaining stiffness during machining and processing.

Features

- Ideal for accelerating and moving low to very high masses — greatest rated thrust force per size

- Suitable for global markets — 230/400/480 VAC bus voltage

- Very smooth velocity with high positional accuracy — zero backlash or compliance, maintaining the stiffness required for machining and other process forces

- Zero maintenance — eliminates lubrication and wear of ball screws, gearboxes, rack and pinions, or belts and pulleys

- Simple, compact mechanical assembly — high force density in a minimal form factor with a greatly reduced total parts count

Iron Core Specifications

| Max. Force – Natural cooling | ||||

| Continuous | Peak | |||

| N | (lbf) | N | (lbf) | |

| IC11 | 140 to 1434 | 31.5 to 322 | 369 to 3348 | 83 to 752 |

| IC22 | 283 to 2806 | 64 to 631 | 741 to 6646 | 167 to 1494 |

| IC33 | 424 to 4311 | 95 to 969 | 1112 to 10042 | 250 to 2258 |

| IC44 | 568 to 5834 | 128 to 1312 | 1486 to 13448 | 334 to 3023 |

| ICD05 | 57 to 157 | 12.8 to 35.3 | 165 to 588 | 37.1 to 132 |

| ICD10 | 104 to 315 | 23.4 to 70.8 | 330 to 1099 | 74.2 to 247 |

| Max. Force – Water cooling | ||||

| Continuous | Peak | |||

| N | (lbf) | N | (lbf) | |

| IC11 | 251 to 2013 | 56 to 453 | 384 to 3141 | 86 to 706 |

| IC22 | 512 to 4012 | 115 to 902 | 777 to 6270 | 175 to 1410 |

| IC33 | 761 to 6021 | 171 to 1354 | 1160 to 9411 | 261 to 2116 |

| IC44 | 1019 to 8211 | 229 to 1846 | 1549 to 12705 | 348 to 2856 |

Download the Direct Drive Linear Motor Selection Guide – IC Series Performance Comparison and Sizing